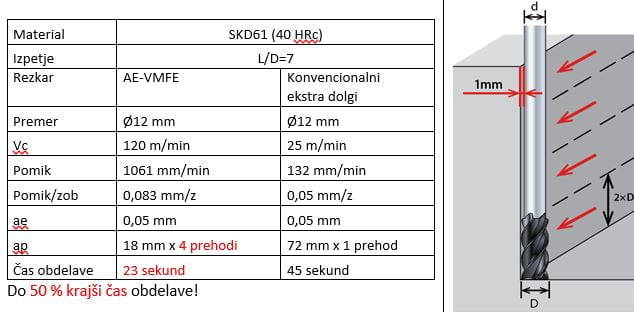

OSG has introduced anti-vibration end mills of the AE-VM series for processing a wide range of materials such as carbon, alloy, stainless steels, and gray cast iron. They achieved reduced vibrations and stable processing by changing the helix angle and increasing the core diameter. The series is complemented with AE-VMFE mills, designed for side milling of greater depths, achieving up to 50% shorter processing time compared to conventional mills with long helix. AE-VM mills are designed for efficient processing of steels up to 55 HRc, gray cast iron, as well as Ti-alloys and Inconel. They feature a sharp positive cutting edge angle reducing cutting force by up to 10%, generating less heat during cutting to prolong end mill life. Uneven tooth spacing and variable helix angle reduce vibrations while cutting, resulting in significantly reduced burrs on workpiece edges. The mills are coated with a Duarise coating which is very smooth, providing good lubricating and sliding properties and a high oxidation temperature. The multi-layer coating is resistant to cracks from thermal stress during cooling with emulsion. Standard AE-VMS mills, short AE-VMSS, long AE-VML, and AE-VMFE for greater depth processing are included in the series. AE-VMS(S)-RA mills are specially designed for achieving perpendicular processing, featuring a unique cutting edge design that eliminates uncut material in workpiece corners. Long AE-VML mills are suitable for cutting depths up to 4xD, with a larger variable helix angle of 42-44°. The core thickness increases conically from the nose to the shank, enhancing the mill's rigidity and reducing deflection at greater side depths. This type of mill is also available with chip breakers on the cutting edge, ideal for trochoidal milling. Additionally, the series includes AE-VMFE mills for side milling of greater depths. Featuring a shank thinner than the blade diameter, they provide smooth access to deeper depths without leaving marks on the workpiece. The cutting edge has a radius transition to the shank to prevent marks on the workpiece, typical of most mills. They have geometry for vibration reduction with uneven tooth spacing, a variable helix angle of 40-44°, and a micro-relief. The micro-relief creates a primary relief surface near the cutting edge, very short to reduce tool friction while still guiding the tool. The helix has a length of 2.5xD. Side milling of greater depths is achieved by multiple passes with depths up to 2xD. Through high feed rates, multiple passes are performed significantly faster than with a conventional extra-long helix mill in a single pass.